Vacuum Casting Services

Low Volume, Durable Parts with Production-Level Quality Delivered Within 7 Days.

Competitive Pricing

High-quality parts at low cost

6000+ Happy Clients

Including ISRO, DRDO, & TATA

One Stop Platform

Track your Vacuum Casting

Priority Delivery

End Parts delivered in 7 days

Design Protection

Proper Legal NDA Agreement

JOIN 6000+ HAPPY BUSINESSES

"We've always had a great experience with Makenica. They've executed our designs on a budget and gone the extra mile for last minute rush prints. A big thank you to Vishal and the Makenica team to enable us to put our best foot forward to our clients and stakeholders!"

— Akbar Ladak

"Best in class 3d printing service and service at the affordable cost and mechanica provides discounts on next printings"

— Kalpesh Bohra

"Wonderful experience working with Makenica™ Inc Works, they provide one the best 3D printers and excellent service✌️. DSATM"

— Nabihul Qamar

"They are one of the best 3D printing services in India. Fine and accurate printing at affordable rates."

— Prajjalak Chattopadhyay

“We have a India-wide supply chain that demands immediate response. Makenica came to us with creative, cost saving solutions related to manufacturing management. Last year we identified a 26% savings across our product fabrication.”

— Praveen Khichar

"Dealing with manufacturing on a day-to-day basis has proved to be very easy with Makenica. We make a telephone call, look at the options available, and then let Makenica get on with the job while we concentrate on our business.

— Rakshak Verma

"Great job...thank you for getting our vacuum casting parts to us in an extremely short amount of time. They also showed us ways to reduce costs in supply chain efficiencies. Team Makenica are always responsive and I know I can count on them to deliver.”

— Samiksha Sud

"I had been there with a design and a lot of doubts, came out satisfied and honestly, awestruck. I see this company becoming really big shortly."

— Tejas Udupa

"One of my friends suggested this place, they helped me with everything from getting the order to delivering it exactly how I wanted it to be. I'm glad she did."

— Vrinda Raj

HOW DO WE DO VACUUM CASTING?

Reliable access to low-cost, high-quality vacuum cast or urethane casted parts.

Over 5 machines, 53 employees, 9 industrial materials & dedicated QC Team.

STEP-1 : ONLINE VACUUM CASTING SERVICE

UPLOAD DESIGN

For Vacuum Casting Service, send us your designs at support@makenica.com or upload your file here by clicking here

STEP-2 FOR ONLINE VACUUM CASTING SERVICE

SLA MASTER MOLD

In order to create the silicon mold, we need to make a highly finished SLA Mold that will create as a Master Design

STEP-3 FOR ONLINE VACUUM CASTING SERVICE

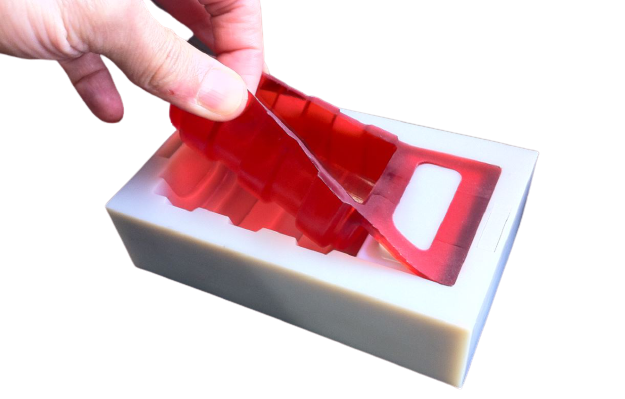

MAKE SILICON MOLD

The master design is immersed in melted silicon to form a mold cavity. This mold cavity is further cleaned to remove any unnecessary details.

STEP-4 FOR ONLINE VACUUM CASTING SERVICE

PRODUCING PARTS

We start filling the desired resin and let it cure for a few hours before taking them out. This cavity mold lasts for 15 to 25 runs depending on the complexity of the product design.

CHOOSE FROM OVER

Industry Certified Materials

ABS PR700

Best alternative to ABS Thermoplastics. This resin vacuum casting material has HDT 130° C.

Polypropylene PR777

Best alternative to PP Thermoplastics. This resin vacuum casting material has HDT 95° C.

Pure Nylon

Nylon offers strong mechanical properties and excellent flexibility. Closest PA12 alternative available.

Rubber 10D-90D

Rubber Resin allows high flexibility and strength. The output parts are designed for end-use case.

Food Grade Safe

US and EU approved list of food-grade safe materials. The outputs can be deployed for user testing.

PMMA & Tint

Best suited for optical prototyping, manufactured with EU Directives: 2011/65/UE (ROHS)

Learn More

Supplementary Services

Get access to low-cost, high-quality custom CNC machining service for complex designs

- Complete CNC Turning

- Full 3-axis CNC Milling

- 5-axis CNC Machining

LASER SERVICES

Laser Cutting and Laser Engraving service. Delivery as fast as 6 hours

- Wood Laser Cutting

- Sheet Metal Cutting

- Acrylic Laser Cutting

- PCB Laser Cutting

INJECTION MOULDING

Traditional Manufacturing Process to scale production from 100 units to ∞ units.

- Aluminum & Steel Molds

- Lead Time 6 weeks

- 200+ Materials

- 100+ output finish options

3D PRINTING - ADDITIVE

Prototype to Production with over 7 different 3D printing methods such as:

- FDM, SLA, SLS

- MJF, DMLS, Polyjet

- Lead Time 2 Days

- 100+ Materials Available

PRODUCT PACKAGING

From packaging design to delivery, everything is taken care by our experienced team :

- Custom Product Packaging

- Free Samples

- 28+ packaging materials

- 50+ papers finish

SHEET METAL FABRICATION

Sheet metal forming, bending, punching, stamping as low as 5 pieces:

- 30+ Metals instock

- Delivery in 5 days

- Output Capacity: 10 million units

- High Tolerance across services

LEARN MORE

About Vacuum Casting Service

Vacuum Casting is used for the production of low volume production (<200 nos) of functional plastic parts. This is achieved using two-component polyurethanes and silicone molds, Vacuum Casting is known for its fast production of high-quality prototypes or end-use products while being highly affordable.

The vacuum casting process is a casting process which is used for the manufacturing of small numbers of highly accurate polyurethane prototype parts of functional materials usually plastic, rubber and metals.

with characteristics and quality comparable to the final product.

This is a slower process than SLA as it requires the additional steps involved in the process, some of which are intensive.

Vacuum Casting also known as Silicone molding produces high-quality parts comparable to injection-molded components. This makes vacuum casted models especially suitable for fit and function testing, showcase materials, marketing purposes, or a series of end-use parts in limited quantities (< 200 nos). Vacuum Casting offers a variety of finishing degrees, and we can even match the finish you need for your parts.

Vacuum Casting is also known as Silicone Molding and is referred to as Silicone Molding since it uses Silicone as the primary material for mold making.

Urethane is the scientific name for Silicone Resin using which the main mold is created. In some industries, vacuum casting or silicone molding is referred to as Urethane Casting Process.

While Urethane Casting seems easy, it carries many nuances that make or break your end-parts finish. Here is an overview of the process:

- Step 1: Getting the 3D Design Ready

- Making a product design that confirms with the tolerances will reduce costs as well as time.

- Step 2: High-Quality Master Model

- We fabricate an ultra-realistic model of your design using SLA Process or Polyjet FDM 3D Printing.

- We double-check the dimensions and looks of the Master Model as per the end results we wish to achieve.

- Step 3: Making the Mold Cavity

- The master is immersed in silicone to form the master mold

- The mold is cured under high temperatures to ensure that silicone toughens.

- Then the mold is cut open into two parts which can be stick together again. This is used to strengthen the mold and make it more durable.

- Step 4: Producing Parts from the Mold Cavity

- We fill the opening of the Mold Cavity with the desired materials and let the resin material cure itself into the shape as per the specs of Master Pattern.

- After a few hours, we open the mold and repeat the above steps.

- Step 5: Discarding the master mold

- It is advised to discard the master mold after 15-20 runs per mold.

- We re-make the master mold using the Master Pattern until the Master Pattern can withstand extreme temperatures of the Silicone without losing its dimensional accuracy.

That's it. In order to get a quick quotation for Vacuum Casting Service, click here

The process is carried out in steps: -

- Have A High-Quality Master Model

The first step in Vacuum Casting is to generate a high-quality surface finish master model, either using Stereolithography or Laser Sintering.

Followed by casting silicone around the master copy, partially under vacuum to avoid air bubbles.

The master model being used is made with utmost attention in dimensions and looks to make sure that no flaws are transferred to the model prototype after finishing the process.

- Cure Process

In Next step, the master model is enclosed into a two-part silicone rubber mold.

The mold is then cured under high temperatures to ensure that the two parts stick together.

After this, the silicone mold is cut according to pre-defined parting planes and the master is removed, leaving a cavity to make copies.

After the mold is cut into two, it is kept in the vacuum chamber.

- Filling the resin

In this step, fill the mold with the designated material.

The resin material is sometimes mixed with metallic powder or any coloring pigment to achieve aesthetic or specific functional properties.

Later it is placed in the vacuum chamber to ensure that there are no air bubbles in the mold.

- Final cured process

In the final stage, the resin is kept in the oven.

The mold is cured in high temperatures to ensure that the material is strong and durable.

Silicon is removed from the mold so that it can be used in making more prototypes.

At last the prototype is removed from mould and painted and decorated.

The painting and designs are used to ensure that the product has a gorgeous final look.

Here are some of the Vacuum Casting or Urethane Casting Service tolerances:

| Distance Dimensions | +/- 0.010” or +/- 0.003” per inch, whichever is larger, is typical. |

| Shrink Mitigation | A shrinkage rate of +/-0.15% can be expected due to thermal expansion of the liquid, and the response of the flexible mold. |

| Surface Quality | The surface finish is externally smoothed to a glossy, satin, or matte surface. |

| Feature Definition | Extreme sharp corners and small text may appear slightly rounded. |

| Size Recommendation | Parts can be as large as 500mm on any one side. |

The minimum order quantity for Urethane Casting Service is as follows:

- One Master SLA Part

- One Master Mold Cavity

- One Run of Mold Cavity

| Maximal part size | 500 mm (40in) |

| Minimal part size | 1.0 mm (0.04 in) |

| Minimal diameter | 0.6 mm (0.02 in) |

Every Vacuum Casting service order includes our standard inspection file that includes reports and certifications such as:

- Critical dimensions

- Quantity of parts

- Removal of sharp edges and burrs

- Number of parts inspected

- Surface finish

- Threads and tolerances

- Full dimensional inspection report

- Resin material test report

- ISO9001, ISO14001, ISO27001, and IATF 16949 certifications

Every Master Pattern can make up to 3 Mold Cavity and each Mold Cavity can produce 15 to 25 parts based on the product design.

In one total run, you can expect between 45-75 parts from one Master Pattern.

Vacuum Casting offers a variety of industrial-grade materials to suit your end-part needs. Some of those are as follows:

| Nylon-6 (Cast) |

| PP-Like |

| PC-Like (Clear) |

| Acrylic (PMMA) |

| Flame retardant (8263) |

| Nylon-12 (PA 2200) |

| High Temperature |

| Teflon (PTFE) |

| Elastomers |

| ABS-Like |

| PP (Machining) |

| ABS (Basic) |

| ABS |

| PC-ABS (8051) |

| Rubber (VC 3300) |

| Ultra Detail (Vero) |

| ABS Transparent (8095) |

| Nylon (VC 3365) |

| Tough Resin |

| POM (Delrin) |

| ABS Black (PX-223HT) |

| ABS Food Grade (9012) |

| Rubber-Like (Tango) |

| GF Nylon-12 (PA 3200) |

| PLA (Basic) |

| Polypropylene (8045) |

| High Temperature (8060) |

Sadly, vacuum casting doesn't allow much choice when it comes to surface finishes. You can post-process the end-parts to make them look appealing in either Matte Finish or Glossy Finish.

Silicone Molding is a process that every manufacturing company deploys before going into the Injection Molding Process. Here are some of the industries which use Silicone Molding extensively:

- Automotive Mould

- Aircraft Parts

- Home Appliance Mould

- Household Plastic Mould

- Connector Mould

- Crate Mould

- Package Mould

- Cooking Utensils

- Medical Devices

• This method can be opted for producing cost-effective low volume production.

• It can be used to build models and prototypes of any size.

• Pre-launch product testing

• Small series of housings and covers

• Concept models

• Food and Beverages

The food and drinks industry use this product for packaging of their final products.

• Commercial Products

Commercial products include sunglasses, mobile cases, food and drinks packaging, and pens.

• Household Products

Products like washing detergents, food processing, and cosmetics are manufactured using this process.

While there are many benefits to Vacuum Casting Service, we have summed up a few that are highly critical:

- Access to industrial-grade materials

- 80% Injection Molding Quality of the end-part

- Best suited for low volume production

- Low investment in tooling and preparation costs

- Economical and Fastest turnaround time

The vacuum casting process results in high-quality products as compared to injection molded components.

Fine detail to the finished product

High precision in producing exact replicas of a prototype on a large scale.

Every attention to detail is considered and taken into account no matter how complex.

Vacuum casted models are usually used for functioning testing and marketing purposes. The end product has such good finishing that this technique has attracted a large set of the audience towards it.

High quality of the product

resin allows you to choose the right material to be used in making of the final product.

This allows you to have a wider choice of flexibility, hardness and rigidity expected in products.

All this leads to a higher quality of products.

Lowers the production costs

Vacuum casting process is more economical manufacturing method than others as Silicone is affordable as compared to aluminum or steel.

Hence it becomes more cost-effective process as compared to the use of 3D printing.

Ideally one silicone mold can produce up to 20 good replicas but again the capability may vary as per the design complexity & quality acceptance.

A great method when you want to meet a deadline

Vacuum casting is a fast method for low volume production. It usually takes up to seven to ten days to make around 50 functioning prototype parts.

Heat resistance

- Colours and tints

- Fire retardance

- Flexibility and rigidity

- UV stability

Nope. They are the same and sometimes used interchangeably with Vacuum Casting Services.

For a standard part that we checked on our in-house Vacuum Casting Setup, costs for various processes are as follows:

- 3D Printing -> INR 4500 for 1 part

- CNC machining -> INR 7000 for 1 part

- Urethane Casting -> INR 4000 for 1 part

- Injection Molding -> INR 60 for 1 part with the cost of mold starting at INR 70,000

Here are some ways to reduce the overall cost of your vacuum casting process:

- Remove Unnecessary Rounded Internal Corners

- Limit the Depth of Cavities

- Limit Use of Tight Tolerances

- Avoid Flashy Surface Finishes

- Remove Small Text & Lettering

- Avoid Small Features with High Aspect Ratio

- Use Widely Used Materials

- Increase the Thickness of Thin Walls

- Choose Quantity and Turnaround Time Tradeoffs

While there are various methods of choosing the material, the end choice depends on the use case of your product. Nonetheless, here are some metrics which will help you choose the right material:

- Physical appearance quality

- Surface texture/finish

- Transparency/translucence

- Rigidity

- Flexibility

- Strength

- Hardness

- Temperature resistance

- UV stability

- Colour

Vacuum Casting Technical Specifications

Typical lead time | Up to 20 parts in 15 days or less, depends on the part specification and volumes. |

Accurate | ± 0.3% (with lower limit on ± 0.3 mm on dimensions smaller than 100 mm) |

Minimum wall thickness | To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

Maximum part dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

Typical quantities | Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

Color & Finishing | Pigment is added to the liquid polyurethane prior to casting, custom painting and texture. |

Makenica provides the vacuum casting services in all tier-1,2 & 3 cities.

TIER-1 CITIES:

Bangalore

Chennai

Delhi

Hyderabad

Kolkata

Mumbai

Ahmedabad

Pune

TIER-2 CITIES:

Agra

Ajmer

Aligarh

Amravati

Amritsar

Asansol

Aurangabad

Bareilly

Belgaum

Bhavnagar

Bhiwandi

Bhopal

Bhubaneswar

Bikaner

Bilaspur

Bokaro Steel City

Chandigarh

Coimbatore

Cuttack

Dehradun

Dhanbad

Bhilai

Durgapur

Erode

Faridabad

Firozabad

Ghaziabad

Gorakhpur

Gulbarga

Guntur

Gwalior

Gurgaon

Guwahati

Hamirpur

Hubli–Dharwad

Indore

Jabalpur

Jaipur

Jalandhar

Jammu

Jamnagar

Jamshedpur

Jhansi

Jodhpur

Kakinada

Kannur

Kanpur

Kochi

Kolhapur

Kollam

Kozhikode

Kurnool

Ludhiana

Lucknow

Madurai

Malappuram

Mathura

Goa

Mangalore

Meerut

Moradabad

Mysore

Nagpur

Nanded

Nashik

Nellore

Noida

Patna

Pondicherry

Purulia Prayagraj

Raipur

Rajkot

Rajahmundry

Ranchi

Rourkela

Salem

Sangli

Shimla

Siliguri

Solapur

Srinagar

Surat

Thiruvananthapuram

Thrissur

Tiruchirappalli

Tiruppur

Ujjain

Bijapur

Vadodara

Varanasi

Vasai-Virar City

Vijayawada

Visakhapatnam

Vellore

Warangal