Plastic Injection Molding Service Online

Manufacture Low Cost, High-Quality Parts in Volume

Competitive Pricing

High-quality parts at low cost

1500+ Happy Clients

Including ISRO, DRDO, & TATA

One Stop Platform

Track your Injection Molding

T1 Samples Delivery

21 Days Delivery for Samples

Design Protection

Proper Legal NDA Agreement

JOIN 1500+ HAPPY BUSINESSES

"We've always had a great experience with Makenica. They've executed our designs on a budget and gone the extra mile for last minute rush prints. A big thank you to Vishal and the Makenica team to enable us to put our best foot forward to our clients and stakeholders!"

— Akbar Ladak

"Best in class 3d printing service and service at the affordable cost and mechanica provides discounts on next printings"

— Kalpesh Bohra

"Wonderful experience working with Makenica™ Inc Works, they provide one the best 3D printers and excellent service✌️. DSATM"

— Nabihul Qamar

"They are one of the best 3D printing services in India. Fine and accurate printing at affordable rates."

— Prajjalak Chattopadhyay

“We have a India-wide supply chain that demands immediate response. Makenica came to us with creative, cost saving solutions related to manufacturing management. Last year we identified a 26% savings across our product fabrication.”

— Praveen Khichar

"Dealing with manufacturing on a day-to-day basis has proved to be very easy with Makenica. We make a telephone call, look at the options available, and then let Makenica get on with the job while we concentrate on our business.

— Rakshak Verma

"Great job...thank you for getting our vacuum casting parts to us in an extremely short amount of time. They also showed us ways to reduce costs in supply chain efficiencies. Team Makenica are always responsive and I know I can count on them to deliver.”

— Samiksha Sud

"I had been there with a design and a lot of doubts, came out satisfied and honestly, awestruck. I see this company becoming really big shortly."

— Tejas Udupa

"One of my friends suggested this place, they helped me with everything from getting the order to delivering it exactly how I wanted it to be. I'm glad she did."

— Vrinda Raj

OUR INJECTION MOLDING CAPABILITIES

From Prototype to Production, high-quality mechanical parts delivered within days not weeks.

FOR DIY & LOW VOLUME

RAPID MOLD

Rapid prototype tooling uses aluminum inserts to make the tool. This method is only for small quantities up to 10,000 pieces, providing design flexibility, reducing the mold cost and cut down lead-time to around 1-2 weeks.

FOR LOWEST PER PART COST

PRODUCTION MOLD

- Lead Time - 3 Days

- Visually Appealing Surface Finish

- Instant Quotation Available

- A.K.A Stereolithography 3D Printing

FOR LOWEST PER MOLD COST

FAMILY MOLD

Family molds reduce tooling costs by combining similar designs into one single mold. This process is ideal for >10,000 prototypes of various shapes by leveraging the manufacturing efficiency of molding with the flexibility of custom tooling

FOR COMPLEX PARTS

MULTI CAVITY MOLD

Best for high-volume, repeatable parts, multi-cavity molds contain identical cavities to increase throughput and achieve a lower favorable per-unit cost.

CHOOSE FROM OVER

100+ Injection Molding Materials

SLA Normal Resin

SLA Normal Resin comes in multiple colours and is highly precise and is available in matter or glossy finish.

ASA Filament

ASA 3D Filament is optimum choice for functional applications, especially automotive parts. More Brittle Nature

Engineering Nylon 12

Nylon PA 12 has high strength, stiffness, not brittle, absorbs very little moisture, chemical resistant.

Flexible TPU Filament

Flexible TPU Filament is highly flexible, perfect for parts that bend or compress. It can take a lot of wear & tear in its life.

Stainless Steel 3D Print

Metal 3D Printing in Stainless Steel 316L allows to produce corrosion-resistant and functional parts.

Copper Metal 3D Print

Copper Metal 3D Printing is 99.8% pure with high ductility, excellent thermal, and electrical conductivity

Titanium Metal 3D Print

Titanium Metal is strong, incredibly lightweight, & heat and chemical resistant. Comes in Gloss/Matte.

Aluminium Metal 3D Print

Aluminium Metal has high strength, lightweight, high thermal & electrical conductivity and resists corrosion

Engineering Nylon 11

Engineering Nylon PA11 has superior thermal resistance, good elasticity, and high impact resistance

SLA Clear Resin

SLA Clear Resin is a hard, strong material that delivers injection mold-like, surface finish with fine features.

SLA Jewellery Resin

SLA Jewellery Resin is made for delicate geometries, delivers highly precise parts, with no visible layers

SLA Tough Resins can handle bending, compression, stretching, and impacts without breaking. (It's ABS Like Durable)

PC-ABS Filament is the extremely strong, resistant to heat and physical impact. Has Optical Clarity as well.

FDM PLA/ABS Filament

Most common 3D Printing Materials. Good Strength, Good Durability, available in various color options

FDM Wood Filament

FDM Wood Filament is aesthetically beautiful, ideal for visual models. Best suited for architectural models.

FDM PETG Filament

FDM Rainbow Filament

FDM Rainbow Filament looks visually stunning, has silk-like finish, but you can’t predict how end print will look

FDM Carbon Fiber Filament

Carbon Fiber Filament is strong and lightweight material, ideal for real-life applications such as car/drone parts

MJF Nylon 3D Printing

MJF Nylon is glass-reinforced extremely strong and tough material with just enough flex to last long.

SLA Dental Resin

SLA Dental Resin is tooth-colored resin for temporary or permanent crown and bridge restorations, inlays, and veneers

All the materials are readily available to manufacture although certain engineering materials such as PEEK, Nylon will require a certain MOQ

CHECK OUT

Our Manufacturing Work

Supplementary Services to 3D Printing

Other Manufacturing Services

LEARN MORE

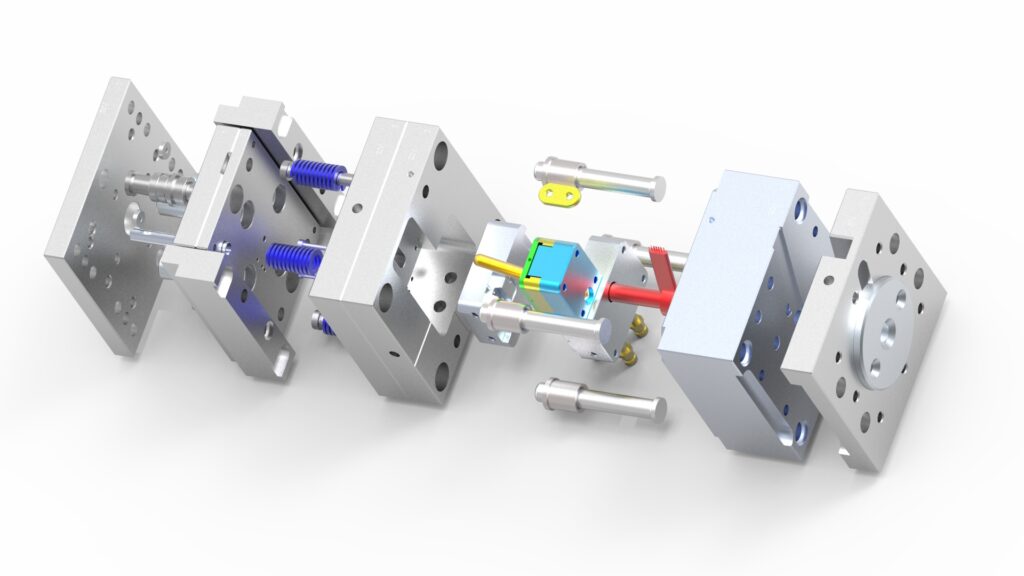

About Injection Molding Service

Plastic injection molding service is the process of melting various plastic pellets (thermosetting/thermoplastic polymers) that once are melted to be malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product using a vertical or horizontal injection molding machine.

We support three types of Injection Molding Machines as follows:

- Horizontal Injection Molding Machine

- Vertical Injection Molding Machine

- Desktop Injection Molding Machine

We support parts that weigh as low as 1 gram to as high as 900 grams.

Horizontal Injection Molding is an Industry standard across many countries due to their ease of use and familiarity. These are best suited for most applications where the part size is large and require industry-standard tolerances

Vertical Injection Molding Machines are an improvement over horizontal machines by improving the tolerances as well as reducing the failure rate. Medical Applications make the most out of it.

The only setback is the limitation of the size of the part manufacturable with Vertical Machine.

Desktop Injection Molding brings the output quality of the professional Injection Molding Machines on a desktop-grade machine.

Suited for a lower number of parts as the cost of parts is higher than the other two injection molding services.

- Wall thickness Thickness: 1 mm and 3 mm

- Smooth transitions 3 × wall thickness difference

- Rounded edges - Internal edges: > 0.5 × wall thickness

- Rounded edges -External edges: internal fillet + wall thickness

- Draft angle - for parts taller than 50 mm: increase the draft by 1° for every 25 mm

- Draft angle -For parts with a textured finish: increase the draft by an extra 1°-2°

The minimum order quantity is 100 runs per mold.

Steel P20, Carbon Steel S50C, Aluminum, and more.

Production inspection reports, full dimensional report, material certifications as well as factory inspection certification available.

| ABS | Acrylonitrile Butadiene Styrene | PC-ABS | PMMA | Polymethyl Methacrylate, Acrylic |

| ASA | Acrylonitrile Styrene Acrylate | PC-PBT | POM | Acetal Polyoxymethylene, Delrin |

| CA | Cellulose Acetate | PC-PET | Polycarbonate-Polyethylene Terephthalate | PP | Polypropylene |

| COPO | Copolyester | PCT | Polycyclohexylenedimethylene Terephthalate | PPA | Polyphthalamide |

| HDPE | High-Density Polyethylene | PE | Polyethylene | PPS | Polyphenylene Sulfide, Ryton |

| LCP | Liquid Crystal Polymer | PE-PP | Polyethylene-Polypropylene | PS | Polystyrene |

| LDPE | Low-Density Polyethylene | PE-PS | Polyethylene-Polystyrene | PS-PPE |

| PA 6 | Polyamide 6, Nylon 6 | PEBA | Polyether Block Amide | PSU | Polysulfone, Udel |

| PA 6/6 | Polyamide 6/6, Nylon 6/6 | PEEK | Polyether Ether Ketone | PVC | Polyvinyl Chloride (Shore D) |

| PARA | Polyaryl Amide | PEI | Polyetherimide, Ultem | PVDF | Polyvinylidene Fluoride |

| PBT | Polybutylene Terephthalate, Valox | PES | Polyether Sulfone | SAN | Styrene Acrylonitrile |

| PBT-PET | | PET | Polyethylene Terephthalate, Rynite | TPO | Thermoplastic Polyolefin |

| PC | Polycarbonate | PLA | Polylactic Acid | TPU | Thermoplastic Polyurethane (Shore D) |

Standard Finish

Moldmaker's choice of finish. Typically SPI B-3 to D-3 depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined.

SPI Finishes

Range of finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1 , SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3

MoldTech Finishes (Mold Texturing)

Range of finishes including matte, swirls, lines, and patterns. Our most common texture finishes include: MoldTech MT11010, MoldTech MT11020, and MoldTech MT11030. Other textured finishes can be added by request.

As Molded

No secondary polishing or grinding. Part will show tooling marks.

Threaded Inserts

We can install most commonly used standard inserts in UNF and metric sizes.

Pad Printing

Transfer a 2D image onto a 3D part. All images are subject to review.

Laser Engraving

Engrave part numbers, logos, and more onto your parts.

Assembly

Makenica has the ability to assemble & label molded parts. Discuss your needs with your salesperson available at support@makenica.com?

Typical tolerances are +/- 0.005" when machining the mold and an additional +/- 0.002"/in when calculating for shrink rate.

Almost any category that sells physical products use injection molding. Some of those industries are:

- Automotive Mould

- Aircraft Parts

- Home Appliance Mould

- Household Plastic Mould

- Medical Molding

- Connector Mould

- Crate Mould

- Package Mould

- Optical Reflectors

- Cooking Utensils

- Medical Devices

- Handles and Knobs

While there are many benefits to Injection Molding, we have summed up a few that are highly critical:

- Detailed Features and Complex Geometry

- Fast production and highly efficient

- High-output production

- Large material choice

- Product consistency

A mold core is a device used in casting and moulding processes to produce internal cavities and re-entrant angles. The cycle begins when the mould closes, followed by the injection of the polymer into the mould cavity.

If we skip the cost of injection CNC mold then the same part would cost as follows:

- 3D Printing -> INR 4500 for 1 part

- CNC machining -> INR 7000 for 1 part

- Urethane Casting -> INR 4000 for 1 part

- Injection Molding -> INR 60 for 1 part

The cost of injection mold starts from $1000 or INR 60,000

Here are some ways to reduce the overall cost of your injection molding manufacturing:

- Eliminate undercuts (highly effective)

- Get rid of unnecessary features

- Use a core cavity approach

- Reduce cosmetic finishes and appearances

- Design self-mating parts (avoid snap-fits)

- Modify and reuse existing moulds

- Get Professional DFM analysis done

- Use a multi-cavity or family mould

- Consider reducing the overall part size

In soft-tooling, the injection mold is made out of Aluminium which is easier to CNC which results in reduced mold cost. (Mold Life: ~50 Thousand)

Whereas, hard-tooling is made using steel which lasts longer than Aluminium mold but has a higher upfront cost. (Mold Life: >500 Thousand)

Bangalore Office

Locations

Makenica™ JP Nagar | 3D Printing Services in Bangalore | Rapid Prototyping Services, SLA/SLS | 3D Printers

1st floor, 1974, 8th Main, Vikram Nagar, Stage 2, Kumaraswamy Layout, Bengaluru, Karnataka 560078

Office Timings

| Monday | 10am–8pm |

| Tuesday | 10am–8pm |

| Wednesday | 10am–8pm |

| Thursday | 10am–8pm |

| Friday | 10am–8pm |

| Saturday | 10am–8pm |

| Sunday | Closed |

Makenica™ | ISRO | Human Figurines | 3D Printing Services in Bangalore | SLA/SLS | 3D Printers

Online 3D Printing Service

#176, 5th Cross, 11th main Bikasipura, ISRO Layout, Bengaluru, Karnataka 560061

Office Timings

| Monday | 10am–6.30pm |

| Tuesday | 10am–6.30pm |

| Wednesday | 10am–6.30pm |

| Thursday | 10am–6.30pm |

| Friday | 10am–6.30pm |

| Saturday | 10am–6.30pm |

| Sunday | Closed |

Makenica™ Inc

Online 3D Printing Service

SLA, SLS, FDM, DMLS,

Injection Molding

#1216, 3rd Floor,14th main, 22nd Cross Rd,

opp. Born babies, 3rd sector, HSR Layout,

Bengaluru, Karnataka 560102

Office Timings

| Monday | 10am–6pm |

| Tuesday | 10am–6pm |

| Wednesday | 10am–6pm |

| Thursday | 10am–6pm |

| Friday | 10am–6pm |

| Saturday | 10am–6pm |

| Sunday | Closed |

Makenica Inc 3d Printing Services

CAD Design Services, Vacuum Casting

CNC Tooling, Laser Cutting, PCB Designing, Mould Making

7, 14th Main Rd, Sector 5, Sector 7, HSR Layout, Bengaluru, Karnataka 560102

Office Timings

| Monday | 10am–6pm |

| Tuesday | 10am–6pm |

| Wednesday | 10am–6pm |

| Thursday | 10am–6pm |

| Friday | 10am–6pm |

| Saturday | 10am–6pm |

| Sunday | Closed |

Makenica™ Whitefield - 3D Printing Services in Bangalore | Rapid Prototyping Services, SLA/SLS | Vacuum casting

Brigade IRV, 9th & 10th Floor, Nallurhalli, Whitefield, Bengaluru, Karnataka 560066

Office Timings

| Monday | Open 24 hours |

| Tuesday | Open 24 hours |

| Wednesday | Open 24 hours |

| Thursday | Open 24 hours |

| Friday | Open 24 hours |

| Saturday | Open 24 hours |

| Sunday | Closed |

Makenica™ USA - 3D Printing Services in Bangalore | Rapid Prototyping Services, SLA/SLS | Vacuum casting and 3D Printing Farm

109 Wales Ave, Jersey City,

NJ 07306, United States of America

Office Timings

| Monday | 10am–8pm |

| Tuesday | 10am–8pm |

| Wednesday | 10am–8pm |

| Thursday | 10am–8pm |

| Friday | 10am–8pm |

| Saturday | 10am–8pm |

| Sunday | Closed |